SPECIFICALLY DESIGNED FOR LOW TEMPERATURE DRYING

OF HIGHER DENSITY PRECISION WOUND YARN AND

THERMALLY SENSITIVE FIBRES |

Conveyor

Dryer

|

|

-- |

|

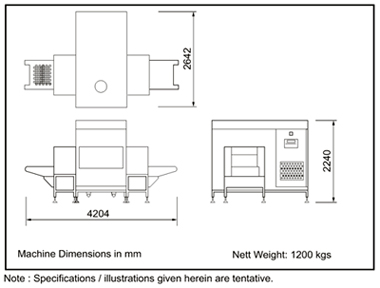

The unique SO-15T Radio Frequency textile dryer from Strayfield The SO-15T equipment offers a cost effective method of drying smaller textile batches. Designed to process all types of textile materials like fibre, hanks, muffs, tops, and yarn packages wound on Polypropylene Centres, S.S. Dye springs, Cones and Cheese. The SO-15T features benefits of flexibility, precision and efficiency at low rates of electric consumption similar to higher capacity conveyorised dryers. |

|

.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Strayfield Limited Ely Road, Theale, Berkshire England RG7 4BQ Telephone: +44 (0)870 428 1086 Fax: +44 (0)870 428 1087 E-mail: info@strayfield.co.uk Website: www.strayfield.co.uk |

|

|

|