The Article below was published in Biscuit World Issue 4 Vol 7 November 2004 :

Radio Frequency Heating and Post-Baking

- A maturing Technology that can still offer significant benefits

by Tony Koral, Technical Director, Strayfield, Ltd

Download a .pdf version of this article here

Radio Frequency (RF) heating and Post-Baking (also known as dielectric heating) is not a new technology and has been successfully used in bakeries for over 40 years now. During this time, there have been significant and continual advances in the design of the equipment. These developments have improved the quality and reliability of the RF ovens out of all recognition from the early machines which were renowned for being temperamental and difficult to maintain. Today's machines, when correctly designed, operated and maintained are now considered by users to be some of the most reliable machines in the bakery.

For many years now, improvements in conventional oven designs and burner controls have been heavily marketed as solving the traditional problem of product checking, thereby offering the possibility of eliminating the need for RF post-baking. However, in reality, as line widths have increased, variations in product moisture uniformity between the centre and edges of the conventional baking band have shown little, if any, improvement over the years.

Checking

Have you ever purchased a packet of biscuits from the local supermarket and moaned about the fact that a large number of them were broken? Usually, this breakage is not caused mechanically (i.e. by dropping the packet, it is due to a phenomenon called product checking.

Checking arises due to the build-up of stresses in the product piece. These stresses are caused by differential moisture content between the outer surface and the centre bone of the biscuit. Conventional bake-ovens utilise indirect heating methods. Heat is transferred to the material surface only, by virtue of conduction, convection or radiation. This means the heat energy has to pass from the surface by conduction to the interior of the product. Often this can present a problem, because the material itself is a good insulator and as such, it is difficult to get the heat to penetrate to the centre of the product. Therefore the surface dries out, whilst the core or centre of the piece remains high in moisture. (For more details see references 1, 2 and 3).

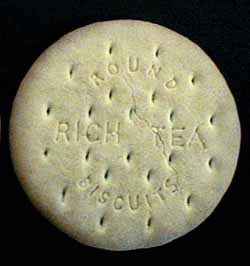

Photo 1 - A good example of a product piece showing classical signs of checking

The photograph (Photo 1 above), shows classical signs of checking. The crack across the centre of the product, caused by excessive build-up of stresses, has clearly not reached the edge of the product yet.

Radio Frequency Post Baking is a proven solution to this problem. For those who are new to RF technology, we need to explain how RF can overcome checking:

How Does RF Heating Work?

The Basic Theory

RF heaters are similar to microwave ovens where products (food, biscuits, paper, textiles etc) passing through the oven (heater), are subjected to a direct or volumetric heating process in the form of a radio frequency (RF) energy source. In the simplest form of RF applicator, the material to be heated is placed between two metal plates which form an electrical capacitor (see Fig. 1). The material becomes a 'lossy' dielectric (hence the alternative name of 'Dielectric Heating') and absorbs energy from the RF Generator which is connected across the two plates (known as 'electrodes').

Generally in most products, we are dealing with water molecules, which are polar, although the technique applies to many other polarisable molecules too. The RF heating process depends upon the ionic conductivity of the material being heated. The effect is analogous to that of two bar magnets. If two like poles are placed together, they repel each other. If two unlike poles are placed together they attract. Similarly, polar molecules have positively and negatively charged ions. If the two electrode plates, between which the material is placed, are charged positive and negative respectively, the molecules will tend to line up all in one direction. If the charge on the plates is then reversed, they will tend to flip around and line up in the opposite direction. Fig. 2 shows the way in which this happens.

Reversing the charge causes the molecules to rub against one another. This causes 'frictional' heating. The heating rate will increase as the frequency of reversal of the charge on the plates is increased. Typically this is caused to occur at high frequencies in the Megahertz range. The RF frequency bands used in dielectric heating are centred on 13.56MHz, 27.12MHz and 40.68MHz. These frequencies are reserved specifically for use by Industrial, Scientific and Medical purposes (I.S.M.) to avoid possible interference with other users of the radio spectrum (i.e. broadcasting, satellites etc.). There are very good technical reasons why most companies in the field use the 27.12MHz band and these are dealt with later in this article.

Power Requirements

The heating effect depends upon the frequency used, the RF voltage field and the loss factor of the material being heated. The loss factor is the product of the Dielectric Constant of the material (er) and the Loss Tangent (tan d). The equation shown below determines the heating effect:

Power/unit volume = 2p f eoer tan d E2 watts - (Equation 1)

Where f = frequency (Hertz)

E = effective applied RF voltage field in volts/metre

eo = permittivity of free space = 8.854 x 10-12 Farads/metre

er = Relative Permittivity of the material to be heated

d = Loss angle (tand = Loss tangent, er.tand = Loss Factor)

The wattage determined by this power calculation refers to the high frequency power output required from the RF generator. When estimating physical requirements, it can be assumed that this figure represents approximately 65-70% of the power taken from the ac supply input. This calculation effectively determines the link between the RF voltage field and the required heating power. To determine the power required to heat a product, a simple sensible heating calculation is used:

Power required = (m. s. DT)/861 kilowatts - (Equation 2)

Where m = mass (kg)

s = specific heat (cal/gm/deg C)

DT = temperature rise (deg C)

This is calculated for both the substrate and the water content (if applicable) and additionally, if the process is a drying process, an additional calculation must be made for the Latent Heat required for evaporation:

Power required = (m. 540)/861 kilowatts - (Equation 3)

Where m = mass of water to be evaporated (kg)

(The specific latent heat of evaporation for water at 100 deg C is 540 cals/gram)

To the power calculated by equations 2 and 3, should be added an amount of energy for radiated heat losses from the product. This will vary considerably depending upon the particular application, but for calculation purposes, a figure of 10% is typically allowed.

Note that this calculation is for the RF power required, not the electrical mains supply power.

The RF energy is produced by an RF 'generator' which basically comprises a power supply, cooling system (air or water) and an electronic oscillator. Typically, the oscillator is powered by an industrial triode tube, and can vary in size anywhere between a few hundred watts and 100 kilowatts or more, depending upon the requirements of the application. A schematic diagram of a simple RF Heating system is shown in Figure 3.

Typical prices vary from around 4000 US Dollars per kilowatt upwards, depending upon the complexity of the machine, although prices start at around 20000 to 30000 US dollars, for even the smallest, most basic machines.

Which Frequency to use?

The vast majority of machines installed for Post Baking applications over the years have operated in the 27.12 MHz internationally accepted (ISM) frequency band. A number of machines have also been installed operating at 40.68MHz, (a frequency which not all countries have adopted as an ISM band). The manufacturers of these machines claim that they operate at a lower RF voltage (given by equation 1 above) and therefore they 'must be less prone to arcing' (flashing to the product). In practice, it has clearly been demonstrated that there is little actual difference between the two frequencies as most incidences of arcing can be attributed not to the machine frequency, but to poorly presented, misshapen or otherwise unsuitable individual product pieces becoming excessively overheated, thereby causing the machine to arc, rather than the other way around.

Experience also shows that the higher 40.68MHz operating frequency also gives rise to a reduction in equipment reliability, mainly caused by the shorter life of the triode tube and other components such as capacitors.

What is the optimum way to present the product to the RF machine?

There are a number of very important factors relating to the way the product is presented to the RF machine which can make a huge difference to its performance. If we examine equation 1 above, we can see that the power per unit volume is proportional to the square of the voltage field. In layman's terms, this means that if you double the amount of product inside the dryer at any one time, the voltage field required to heat the product is very significantly reduced. Therefore, generally the trick is to fill the oven with as much product as possible. In practice, this means that it is advantageous to present products in a bed or shingle-stacked, rather than in a monolayer. This is most important when small product pieces are being processed, or when products such as snack pieces which are liable to misshapes, doubles etc. are run.

A second crucial point is that the RF oven must be mounted as close as possible to the conventional oven mouth. This avoids product heat losses. Product heat losses are important, firstly because additional energy is wasted in re-heating the product before moisture can be evaporated. (This can amount to several extra kilowatts of energy per hour of machine useage). Secondly and more importantly, in order to re-heat the product, these kilowatts of additional energy mean that excessive RF voltage has to be used (again refer to equation 1), which reduces the tolerance of the process to unsuitable product.

Other key benefits to the use of RF in post-baking applications

It is possible to achieve a significant increase in production simply by using RF immediately after the conventional oven. Increases of 40% are common as by adjusting the bake characteristics to provide the desired visual appearance and ignoring the moisture content line speeds can be much improved. The RF machine will then preferentially act upon the water to give the required final moisture content.

Clearly by using RF as opposed to increasing the conventional oven length to achieve increased production there is an important capital saving to be made as well as savings in all important floor space. By ensuring consistently controlled moisture shelf life is enhanced and with sponge products in particular, the formation of mould spores can be significantly reduced.

75kW Strayfield Post Baking Dryer in Stainless Steel.

Strayfield - An Update

Over the past year Strayfield have relocated to newly refitted premises in Theale near Reading, Berkshire. As a member of the Inductoheat Group we now have access to all the group manufacturing facilities, especially those within a 30 mile radius of Theale. This has allowed the Theale site to concentrate on Design, R&D, Final Assembly and Testing.

Strayfield has long has a reputation for the high build quality and longevity of our equipment and the current arrangement allows us to provide ever better service to our large worldwide customer base. The latest food unit was supplied to Japan where the client reports "checking" down from 50% to virtually nil.

List of references:

1. Checking in Cream Crackers - Flour Milling and Baking Research Association Report No 98 (September 1982)

2. A novel application of speckle interferometry for the measurement of strain distributions in semi-sweet biscuits, Q Saleem, R D Wildman, J M Huntley and M B Whitworth, Institute of Physics publishing, Measurement Science and Technology, Meas. Sci. Technol. 14 (2003) 2027-2033

3. Increased Productivity by Dielectric Heating - Paper given to the BCMA Conference, 1979, John M. Holland.